& ※ Related Recommended: 【High-speed steel straightening machine, steel straightening machine specifications】 Luoyang Hong special machinery and equipment Co., Ltd. is the main business, our company was originally China South Locomotive Group Luoyang Locomotive Factory repair machine factory, in 2004 according to the state The relevant provisions of the restructuring for the Luoyang Hong special machinery and equipment Limited. The company mainly for the steel straightening cutting machine manufacturing sales, machinery and equipment overhaul, non-standard equipment manufacturing. The company is strong in technology, well-equipped, high technical staff quality. The company developed high-efficiency steel straightening cutting machine has reached the advanced level of similar foreign products, high efficiency, good quality, by domestic and foreign steel dealers, steel welded wire mesh production enterprises, steel distribution centers and other users of praise. Products have been exported to Laos Myanmar Southeast Asia, Taiwan and Europe. Welcome friends from all walks of life patrons, visit the guide.

High-speed steel straightening machine / steel straightening machine specifications for more information

Brand: Hunt

High Speed Steel Straightening Machine Model: GT Series

Product alias: steel straightening machine

Product use: steel straightening and cutting cut

High-speed steel straightening machine type: steel straightening machine

Operation Rules for High - speed Steel Straightening Machine / Steel Straightening Machine Specification

1, the equipment must be responsible for the person, and holders of posts.

2, high-speed steel straightening machine operators are not allowed to leave the machine too far, on the plate, wearing silk, the first cut off must be shut down.

3, straightening the process of steel, when the steel out of the tray guide slot, the top fixed body and the chaos or steel bar off, should promptly press the limit switch, stop cutting steel, to be adjusted after the prospective use The

4, each steel bar to adjust to the end or straightening short steel bars, should be hand-held pipe escort guide to the guide and straighten the drum, so as to avoid the free swing when the accident occurred.

5, straighten the mold is not fixed, the protective cover is not covered before, are not allowed to penetrate the steel bar, to prevent the machine after the start, straighten the mold flew out of injury.

6, machinery in the course of operation, shall not adjust the drum, with gloves is strictly prohibited operation, and is strictly prohibited in the process of mechanical maintenance operations.

7, has been straightened, cut off the steel, should be according to specifications, the number of roots divided into small bundles neatly, not allowed to chaos, to prevent the composition of steel, performance caused by different quality accidents, operations must be cut off the power.

8, high-speed steel straightening machine strict implementation of the "cross operating principles" to ensure that the machinery is in good working condition.

High - speed steel straightening machine / steel straightening machine specifications of the technical parameters

.jpg)

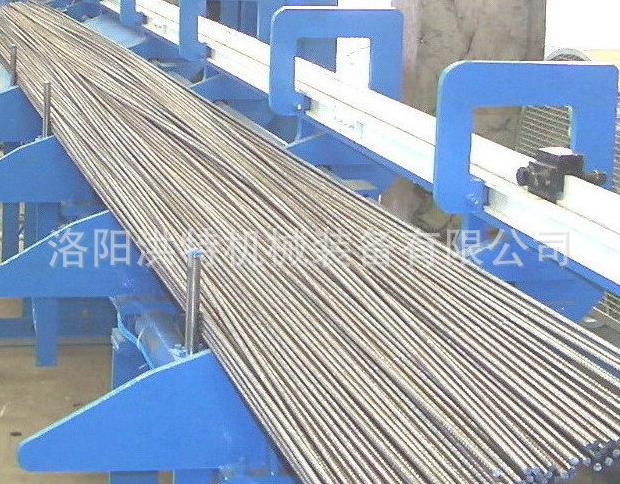

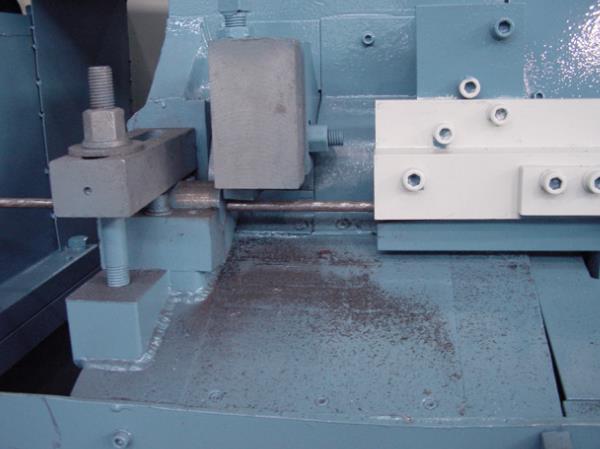

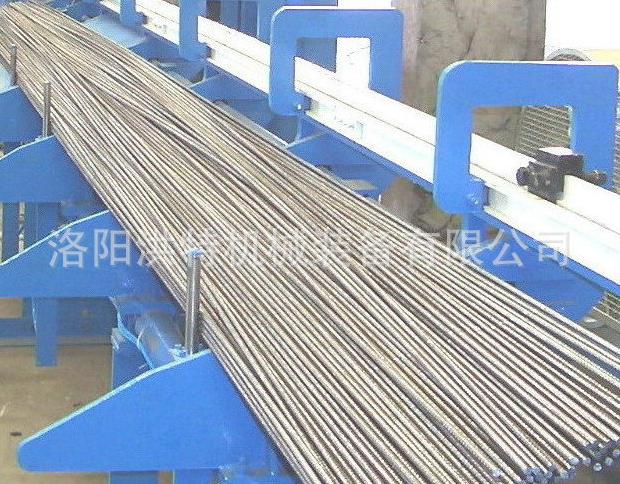

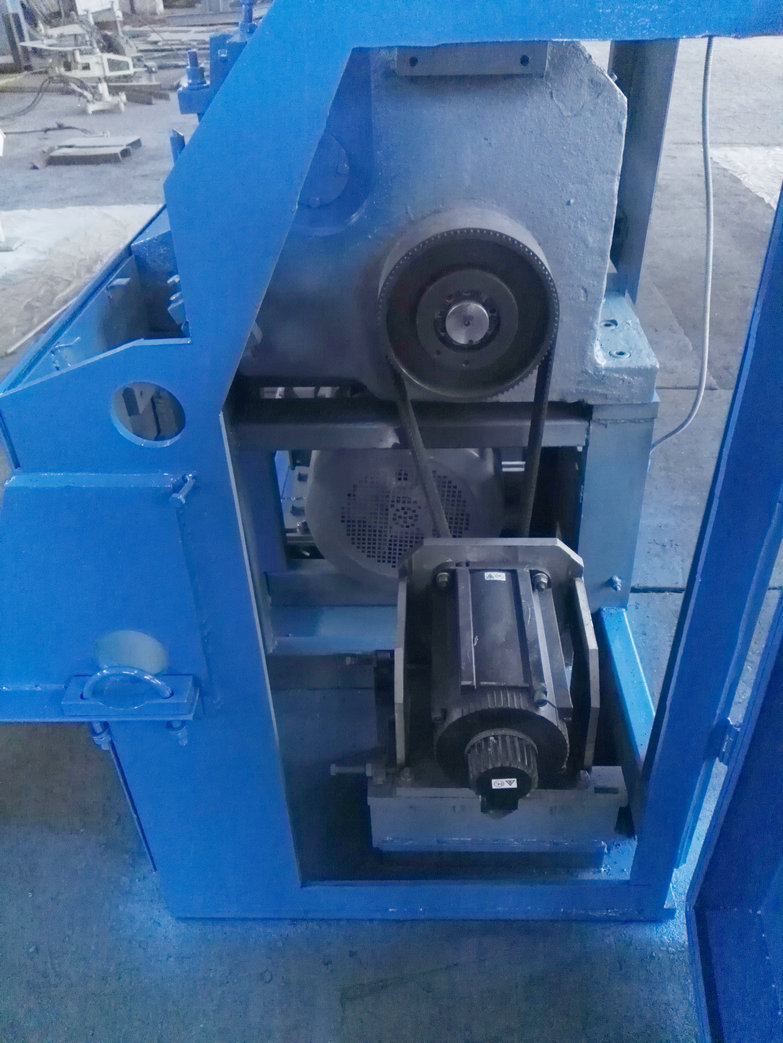

High-speed steel straightening machine / steel straightening machine specifications of the product display